-

Email

signovatedesign@gmail.com -

Phone

+(91) - 9899969180 -

Address - India (Delhi)

A4/1, Phase 1, Naraina Industrial Area, Opp. PVR Payal Cinema, New Delhi – 110060 -

Address - Australia (Sydney)

Unit 6, 276/278 Victoria Street, Weatherill Park, NSW 2164, Sydney, Australia

© Alrights reserved

by Signovate Signs

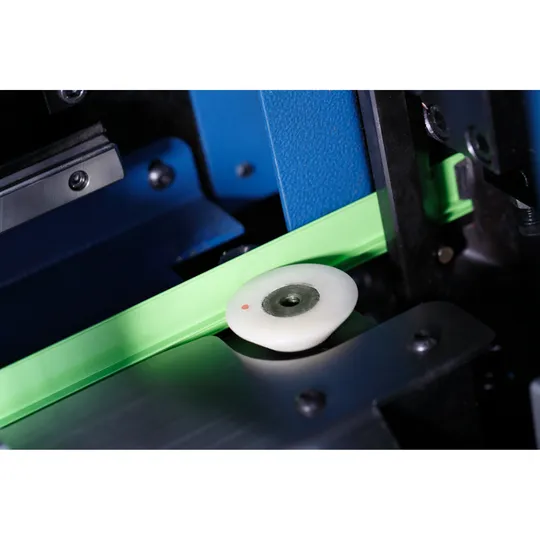

TPS Automatic Multi‑Functional Channel Letter Bending Machine (Model TP‑S9710)

The TPS Automatic Multi‑Functional Channel Letter Bending Machine (Model TP‑S9710) is a high‑precision CNC workhorse designed for bending, slotting, notching, and flanging a broad range of materials—stainless steel, aluminum, galvanized steel, strip metal, and aluminum profiles—into custom channel letters and signage components. With its advanced 7‑axis control system driven by four servo motors and three stepper motors, it delivers exact V‑cuts at angles ranging from 45° to 140°, accommodating material heights up to 175 mm (flat) and thicknesses up to 1 mm for stainless steel and 2 mm for aluminum. Operating on a 5 kW AC200V power supply (with optional 0.4–0.6 MPa air assist), it automates feeding, bending, cutting, slotting, and angle trimming for both sheet and profile work. With a 900 kg frame and CNC‐controlled motion, the TPS S9710 delivers fast, consistent, and complex bends ideal for high‑volume signage shops and fabricators seeking efficiency and accuracy.

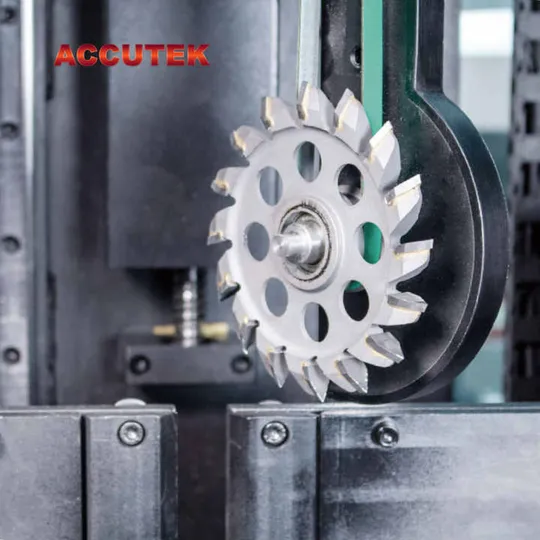

The High‑Precision AT3PLUS Channel Letter Bending Machine is a fully automatic, multifunction CNC system engineered for ultra‑accurate production of 3D channel letters and neon‑style signage. It automatically feeds, slots, bends, and flanges flat metal sheets and profiles—supporting materials such as aluminum alloy, stainless steel, galvanized sheet, brass/copper, and carbon steel—with widths from 25 mm up to 200 mm and return heights between 10 mm and 200 mm. Driven by a 7‑axis control (including four Fuji servos), it delivers impeccable double‑blade alternating bends, precise V‑cuts with alloy milling or plane‑wheel cutters on both sides, and a minimum bend radius of just 6 mm. It reads standard DXF/PLT/AI design files to execute consistent, high‑complexity shapes using sophisticated servo motion and slotting swing calculations, all while powered by a 220 V 50 Hz, 3.5–3.8 kW system—making it ideal for efficiently crafting large volumes of complex, uniformly bent signage parts

High‑Precision AT3PLUS Channel Letter Bending Machine

DOBOSEN Laser Welding Machine

The DOBOSEN Laser Welding Machine is a sophisticated Nd:YAG pulsed laser welding system engineered for precision joining of diverse metals with exceptional speed and accuracy. It projects a high-intensity laser beam through an imported ceramic cavity, producing concentrated heat to melt and fuse materials with minimal heat-affected zones, making it ideal for automotive, aerospace, electronics, jewelry, and medical-device applications. The machine supports workpieces up to 1200 × 800 mm and 200 kg, with pulse widths up to 10 ms, single pulse energies around 90 J, and repetition rates up to 50 Hz. Featuring a 300 W laser output at a 1064 nm wavelength, it utilizes a water-cooling system capable of dissipating 2700 W, and incorporates a red-light indicator plus CCD monitoring for precise weld control. Powered by under 7 kW on a 200 V supply, its standard 1300 mm laser gun (customizable) and compact 390 kg form factor allow it to perform high-quality, repeatable welds on metals ranging from stainless steel to copper, all while maintaining consistent performance and efficiency.

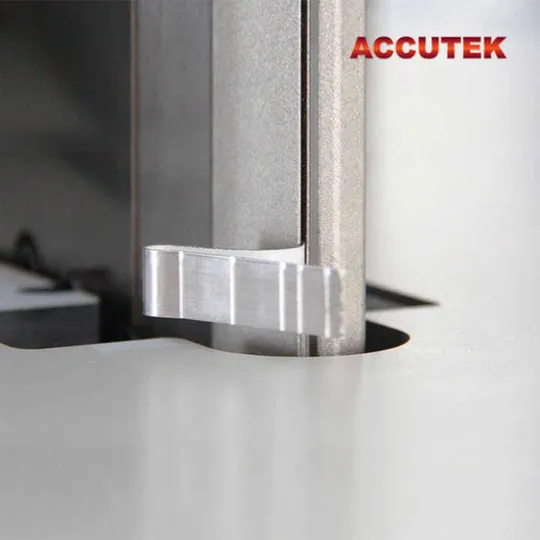

The Dobosen A130 is a fully automated CNC channel letter bending machine engineered for precision and efficiency in signage fabrication. It automatically feeds, slots, and bends flat aluminium sheets and aluminium profile channels—with material heights up to 130 mm and thicknesses up to 1.0 mm—executing slot angles between 45° and 135° using a double‑size swing slotting mechanism and multi‑tooth milling cutters for high‑precision cuts and bends. Operating on 220 V single-phase power with a total power draw of around 1.5 kW, the computer‑controlled system reads DXF/PLT/AI design files to produce trimless, epoxy, liquid acrylic, and classic profile channel letters, achieving tight arcs and smooth flanges. Built on a robust 240 kg frame within a compact footprint (~1250 × 720 × 1300 mm), it delivers reliable, consistent bending performance ideal for high-volume sign, retail display, and interior/exterior architectural lettering

Dobosen A130 Aluminium Channel Letter Bending Machine

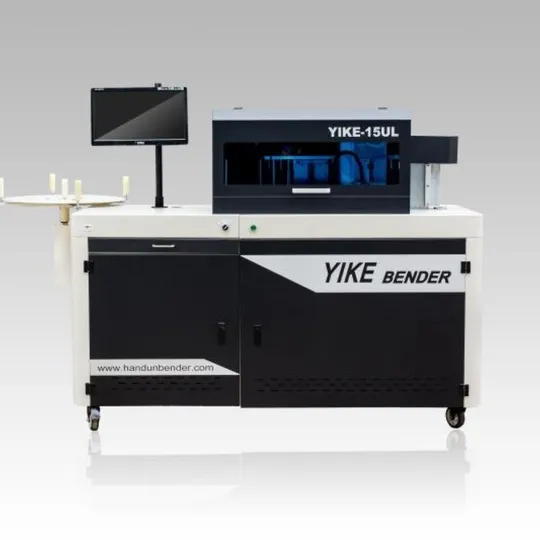

YIKE‑6S‑C CNC Channel Letter Bender

The YIKE‑6S‑C CNC Channel Letter Bender is a fully automatic beading machine designed for efficient, high‑precision production of 3D channel letters used in signage. It automatically feeds flat metal—such as stainless steel, aluminum rolls or profiles, and Channelume—slots, notches, and bends materials ranging from 20 mm to 160 mm in width and 0.3 mm–1.2 mm in thickness. Powered by a 3 kW motor and operating on a 220 V supply, this 400 kg system offers seamless V‑cut slotting and precise bending angles, all controlled by its CNC interface. Built for continuous production, it delivers rapid, uniform bends and slots with minimal manual input, making it an ideal choice for sign-makers seeking consistent quality, speed, and automation in channel letter fabrication.

The TigerTec TR408 CNC Router is a powerful and versatile 4×8 ft machine built for high-precision cutting, carving, engraving, and routing across a wide variety of materials including wood, acrylic, MDF, PVC, aluminum, and brass. It features a heavy-duty, stress-relieved steel frame with a heat-treated gantry for maximum stability and accuracy. Equipped with a high-speed Italian spindle capable of reaching up to 24,000 RPM, it delivers smooth, clean cuts even at high feed rates. The machine runs on rack-and-pinion transmission with linear guide rails across all axes, providing repeatable accuracy of ±0.05 mm. It supports 2D and 3D processing, making it suitable for signage, furniture, cabinetry, and industrial prototyping. The user-friendly CNC control system is compatible with design file formats like DXF, DWG, AI, and EPS, allowing for seamless operation. With options for vacuum hold-down, tool changers, and various table configurations, the TigerTec TR408 is ideal for both batch production and detailed custom work.

TigerTec TR408 CNC Router

Yueming CMH1309‑B‑A Laser Cutting Machine

The Yueming CMH1309‑B‑A is a semi‑automatic CO₂ laser cutting system engineered for precision cutting and engraving of non‑metal materials such as acrylic, MDF, wood, leather, rubber, fabric, crystal, ceramic, jade, and more, across a spacious 1300 × 900 mm work area. It harnesses a 100–130 W laser source with water cooling and a SmartCarver 32‑bit DSP controller that delivers rapid, stable cutting at speeds up to 200 mm/s (and engraving up to 30 m/min), offering accurate path interpolation, dynamic laser spot compensation, and seamless DXF/AI/PLT graphic support. Featuring a closed‑loop motion control system, ±0.1 mm repositioning precision, and comprehensive file format compatibility, this sturdy, ~380 kg platform ensures consistent, high‑quality output for sign‑making, handicrafts, apparel, packaging, and decorative applications — making it an ideal tool for efficient, versatile non‑metal laser fabrication

The FORSUN 3 kW CNC Fiber Laser Cutting Machine is a high-performance industrial solution engineered for ultra-precise and high-speed cutting of various sheet metals including stainless steel, carbon steel, galvanized steel, aluminum, brass, and alloys. Built with a rigid one-piece welded frame, it offers exceptional stability and accuracy, with positioning precision of ±0.02 mm/m and cutting speeds up to 100 m/min. Its advanced Raytools autofocus cutting head automatically adjusts focus based on material thickness, ensuring clean and accurate cuts without manual intervention. Operating with a powerful 3 kW fiber laser source, this machine can handle sheet sizes up to 1500 × 3000 mm efficiently. Controlled by a user-friendly CypCut system, it supports intelligent path planning, nesting, and edge detection while accepting common design file formats like DXF, PLT, and LXD. Ideal for signage, fabrication, and industrial applications, this machine delivers sharp, narrow kerfs with minimal thermal impact, making it a reliable asset for high-volume, precision-driven metal cutting.

FORSUN 3 kW Fiber Laser Cutting Machine

Acctek Acrylic CO₂ Laser Cutting Machine

The Acctek Acrylic CO₂ Laser Cutting Machine is a high-precision CNC laser system specifically designed for cutting and engraving a wide range of non-metal materials such as acrylic, wood, leather, fabric, rubber, paper, glass, and ceramics. It features a sealed CO₂ laser tube with adjustable power ranging from 80 W to 300 W, capable of cutting acrylic up to 40 mm thick with clean, polished edges. The machine includes a precision laser head with red-dot positioning and auto height adjustment, ensuring accurate alignment and consistent cutting depth. Its robust motion system, supported by HIWIN linear rails and reliable stepper motors, delivers positioning accuracy of 0.01 mm and repeatability of 0.02 mm, making it ideal for intricate detailing and repeat production. With working area options up to 1500 × 3000 mm, it supports high-speed operation for both cutting and engraving tasks, making it an essential tool for sign-making, decorative work, packaging die production, and other applications requiring flawless non-metal fabrication.

The handheld fiber laser welding machine is a state-of-the-art tool designed for fast, precise, and efficient welding of metals like stainless steel, aluminum, iron, titanium, copper, and galvanized steel. Powered by a 3000 W continuous-wave fiber laser, it generates a focused energy beam that delivers deep penetration and strong welds with minimal heat distortion and a clean finish. The machine supports multiple welding modes including straight, circular, and wobble patterns, and features an optional wire feeder for enhanced flexibility in joining thicker materials or filling gaps. Its compact, handheld design allows for easy maneuverability and access to complex weld areas like corners, curves, and edges. With the ability to achieve weld depths of up to 12 mm and speeds 4–10 times faster than traditional TIG or MIG welding, it significantly reduces post-processing and labor effort. Ideal for both industrial and fabrication environments, this machine ensures high-strength, aesthetically clean welds while improving productivity and reducing operational costs.

Fiber Laser Welding Machine

HP K570 Large Format Plotter

The HP K570 is a professional-grade large-format inkjet plotter engineered for high-quality printing with a maximum media width of 1,620 mm. Designed to support a wide range of graphics applications, it delivers precise, high-resolution output suitable for signage, posters, banners, and technical drawings. With robust mechanics and advanced inkjet technology, this machine ensures consistent color fidelity and sharp detail across different substrates. Its reliable feed handling accommodates rolls and rigid media, while its precision movement system maintains alignment for long prints, making it ideal for designers, print shops, and industrial users seeking reliable, large-scale graphics production.

Say Hello

Founded in November 1996 by Shri Surender Pal Sachdeva, our company has evolved through a journey of transformation and consistency. Over the years, we’ve adapted to changing times and technologies, always striving to do a little better than we did the day before.

ALL ENQUIRIES

Mon -Sat 10:00 am to 7:00 pm

PICK UP & DESPATCH

Mon – Fri 07:30 am to 15:00 pm

📍 Factory Addresses:

🇮🇳 India (Delhi):

A-4/1, Naraina Industrial Area, Phase-1, New Delhi – 110028, India

🇦🇺 Australia (Sydney):

Unit 6, 276/278 Victoria Street, Weatherill Park, NSW 2164, Sydney, Australia